Breakthrough Precursor Hydrolysis Method Revolutionizes Mass Production of SiO₂ Multi-Shell Hollow Spheres!

2024-11-19

Author: Emily

Introduction

In an exciting development in materials science, a research team spearheaded by Prof. Zhu Qingshan at the Institute of Process Engineering (IPE) of the Chinese Academy of Sciences has unveiled a groundbreaking precursor hydrolysis method (PHM) that promises mass production of silica multi-shell hollow spheres (SiO₂ MHSs). These unique structures—characterized by their porous walls and internal voids—have emerged as game-changers in various applications such as confinement catalysis, energy storage, chemical separation, and drug delivery.

Challenges in Production

Traditionally, scaling up the production of SiO₂ MHSs from laboratory settings to industrial levels has posed a significant challenge for researchers and manufacturers alike. Prof. Zhu’s team has tackled this issue head-on, demonstrating that their innovative approach can effectively bridge the gap between small-scale synthesis and large-scale manufacturing while maintaining the integrity and functionality of the MHSs.

Research Methodology

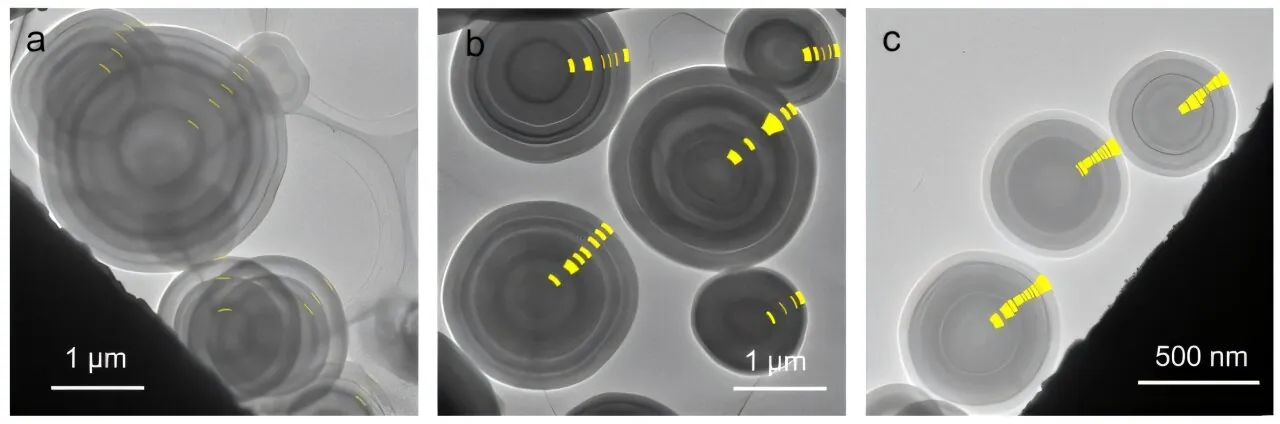

The research, now published in the reputable journal Advanced Materials, illustrates the meticulous process involved in their new method. The team began by creating precursors from SiCl₄ and NH₃ within a fluidized bed reactor, generating a compound known as Si(NH)₂. This precursor was then subjected to hydrolysis in ammonia water at 25°C for a period of five hours. To finalize the transformation into SiO₂ MHSs, the resulting mixture was heated to 60°C.

Findings and Implications

One of the most compelling findings of this study is the team's ability to tailor the properties of the SiO₂ MHSs by varying the hydrolysis medium. By manipulating this aspect, the researchers successfully controlled the void ratios and diameters of the spheres, producing materials with void ratios ranging from 0.05 to an impressive 0.85. This level of control opens up new possibilities for customizing SiO₂ MHSs for specific applications, potentially enhancing their efficacy in fields ranging from pharmaceuticals to renewable energy solutions.

Conclusion

With growing global emphasis on sustainability and efficiency, the ability to produce SiO₂ MHSs at scale could significantly impact industries that rely on advanced materials. As researchers continue to explore the potential of these innovative structures, this breakthrough might just pave the way for the next generation of efficient catalysts and storage systems, ultimately leading to more effective solutions in energy and health sectors.

Future Developments

Stay tuned as more developments unfold in this exciting arena, as the implications of this new method could lead to a revolution in the way we harness and utilize materials for modern applications!

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)