Revolutionary Breakthrough: Sunshine Paves the Way for Effective Recycling of Black Plastics!

2024-11-25

Author: Olivia

Introduction

Researchers have unveiled a groundbreaking method that could drastically change the fate of black plastics, which have long plagued the recycling industry. Black foam from food containers and black coffee lids, often made from polystyrene, typically find their final resting place in landfills due to their dark color and the additives used, which hinder effective sorting. However, hope is on the horizon as scientists announced their findings in the prestigious journal ACS Central Science, highlighting an innovative way to recycle these challenging materials using sunlight and a common additive already present in the waste.

Harnessing Light for Recycling

According to the study's authors Sewon Oh, Hanning Jiang, and Erin Stache, harnessing simple visible light has the potential to revolutionize the chemical recycling of plastics. Their research focuses on an additive called carbon black, commonly found in black polystyrene, which they ingeniously utilized in conjunction with sunlight or white LEDs to transform plastic waste into reusable raw materials.

The Process

This emerging recycling strategy taps into the immense power of light to facilitate the breakdown of plastics into functional materials. The process hinges on the use of a helper compound that can convert light energy into the heat necessary to dismantle polymer bonds. However, the quest for an appropriate helper that does not inadvertently contribute to further waste has proven to be a significant challenge.

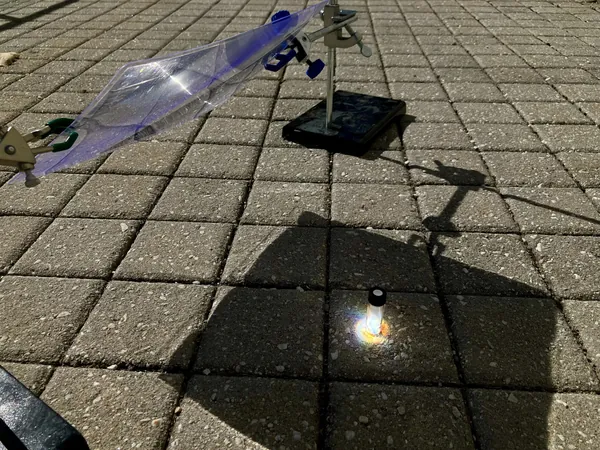

Experimental Setup

Undeterred, Stache and her research team effectively utilized carbon black through their innovative experimental setup. They took laboratory-produced black polystyrene mixed with carbon black, grinding it into a fine powder. Then, interestingly, they placed the mixture in a sealed glass vial and exposed it to high-intensity white LEDs for half an hour. The carbon black efficiently converted the LED light into heat, resulting in the breakdown of the polystyrene's molecular structure into shorter styrene units.

Results and Efficiency

Their efforts yielded impressive results; the researchers managed to recycle the leftover carbon black and styrene monomer back into polystyrene, showcasing the effectiveness of their circular recycling method. Furthermore, when applying this technique to real-world waste, such as used food containers and coffee cup lids, they achieved remarkable success, with up to 53% of the polystyrene converting back into styrene monomer.

Challenges and Discoveries

While samples contaminated with substances like canola oil and soy sauce showed slightly reduced efficiency in the breakdown, the team made a significant discovery: when they swapped the artificial light for concentrated sunlight outdoors, the reaction efficiency surged to 80%. This remarkable finding was further corroborated when they experimented with a mix of colored polystyrene waste, which also showed higher conversion rates under sunlight (67%) compared to white LEDs (45%).

Conclusion

This research not only highlights the potential for a more sustainable future for plastic recycling but also calls attention to the importance of innovative solutions in tackling plastic waste. As the world continues to grapple with the increasing plastic crisis, this method could be a game-changer in creating a circular economy that minimizes environmental impact while maximizing resource recovery.

Final Thoughts

So, could this be the ultimate solution the planet has been waiting for? With the promise of sunshine-driven recycling, it's a bright step forward in the fight against plastic waste!

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)