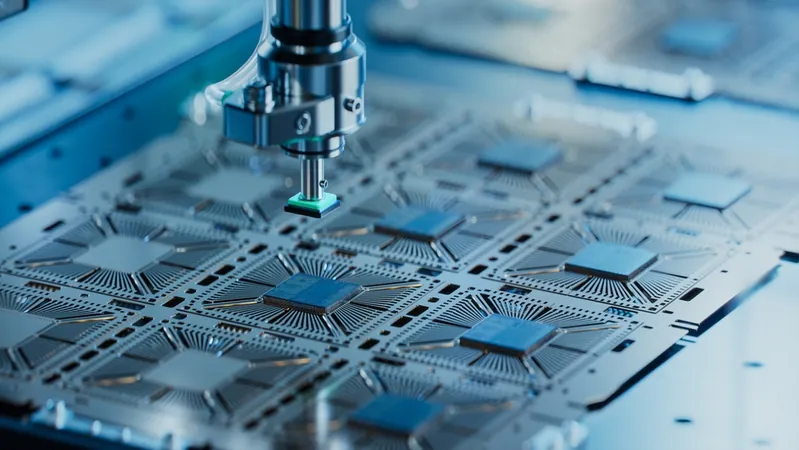

Revolutionary Indium-Based Materials Set to Transform Computer Chip Manufacturing

2024-12-10

Author: Sophie

Introduction

In an exciting development for the tech industry, engineers are on the hunt for new materials to manufacture computer chips, aiming to make them increasingly smaller and more efficient. Faculty members from the University of Dallas, alongside collaborators and industry partners, are pioneering research into indium-based materials that could usher in the next generation of computer chips.

With a substantial grant of $1.9 million spanning three years from the National Science Foundation’s Future of Semiconductors (FuSe2) program, the team is poised to make significant advancements. This grant is part of a larger $42.4 million funding initiative announced in September to support the federal CHIPS (Creating Helpful Incentives to Produce Semiconductors) and Science Act of 2022, which aims to enhance energy efficiency in computing and boost domestic semiconductor production.

Redefining Chip Performance and Efficiency

At the core of this research is the introduction of indium-based materials, which promises to revolutionize the lithography process—an essential step in the semiconductor fabrication sequence. This process involves creating intricate patterns on silicon wafers that serve as the foundation for transistors and various electronic components. The shift from traditional deep ultraviolet (UV) lithography to extreme ultraviolet (EUV) lithography empowers manufacturers to create smaller and increasingly precise features on chips, leading to enhanced performance and reduced energy consumption.

This innovative approach addresses one of the significant challenges in semiconductor manufacturing: the limitations of conventional photoresist materials when exposed to high-energy EUV photons, which require a more sophisticated material solution.

Moreover, the research is not just focused on 2D chip designs. The team is exploring the potential for 3D integrated circuits, which involve stacking layers of chips. This cutting-edge technique necessitates materials capable of supporting additional layers without compromising existing circuitry—a complicated but achievable feat with the new indium-based materials.

Enhanced Semiconductor Properties Without the Heat

Dr. Julia Hsu, a prominent figure in this research and a professor of materials science and engineering, emphasizes the importance of keeping temperatures low during the layering of devices. "If you are making a layer of devices on top of another layer of devices, heating them excessively can damage the existing layers,” she explains. By leveraging indium-containing materials as EUV photoresist and transistors, the researchers foresee an elimination of solvent-based steps traditionally involved in circuit manufacturing, thereby boosting efficiency and performance.

Additionally, they are testing a method known as photonic curing, which employs high-intensity but low-energy light pulses. This technique facilitates critical chemical reactions, allowing indium oxide to attain superior semiconducting properties without risking damage to underlying structures.

Integrating Machine Learning for Smarter Solutions

Dr. Hsu intends to incorporate machine learning into their methodologies, an innovation supported by a 2023 Simons Foundation Pivot Fellowship. This integration aims to refine the design and testing processes further, expanding the horizons of existing commercially available materials and enhancing the overall project scope. "The FuSe2 project will enable us to take our preliminary results to a much higher level and bigger impact,” Dr. Hsu states.

Collaboration at Its Best

The project benefits from the expertise of co-principal investigators Dr. Cormac Toher and Dr. Kevin Brenner, both of whom are assistant professors in materials science and engineering. Toher is tasked with designing the indium-containing molecules, while Brenner focuses on fabricating and testing the devices. Together, they aim to create a thriving research ecosystem that also includes workforce training initiatives through UTD’s North Texas Semiconductor Institute, targeting community college students.

A Game Changer for Technology

As the world becomes increasingly reliant on technology, the push for more efficient, powerful computer chips is more crucial than ever. With the innovative minds at the University of Dallas leading the charge in indium-based materials research, we could soon witness a significant paradigm shift in semiconductor manufacturing that will redefine the capabilities of electronic devices for years to come. Stay tuned as we bring you more updates on this groundbreaking project that promises to reshape the future of technology!

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)