Revolutionary Multi-Directional Artificial Muscles: The Future of Robotics and Medicine

2025-03-18

Author: Emma

In a groundbreaking development that could change the landscape of robotics and medical applications, researchers at MIT have unveiled the first-ever multi-directional artificial muscles. These innovative muscle tissues are set to mimic the complex movements of natural muscles, opening the door to advanced biohybrid robots and sophisticated medical technologies.

From Nature to Machines: The Quest for Flexibility

The human body demonstrates remarkable complexity in movement thanks to the coordinated effort of skeletal muscles, functioning in both linear and intricate patterns. Until now, scientists have grappled with replicating this complexity in artificial systems. Traditional robotic actuators are predominantly rigid, limiting their functionality and adaptability. However, biohybrid robots powered by lab-grown muscle tissues promise a new, flexible alternative that could be more energy-efficient.

The challenge has been in engineering artificial muscle tissue capable of contracting in multiple directions. Earlier methodologies primarily yielded unidirectional muscle fibers, which severely restricted their ability to replicate the dynamic capabilities seen in natural muscles, such as those found in the iris or even in our limbs.

The STAMP Method: A Game Changer in Muscle Engineering

The team at MIT has pioneered an innovative technique dubbed “simple templating of actuators via micro-topographical patterning” (STAMP). This exciting method facilitates the growth of contractile muscle cells along specially designed microscopic patterns in hydrogels, enabling complex, multi-directional muscle architectures to develop.

By employing cost-effective 3D-printed stamps, researchers have successfully created grooves within soft hydrogels that mimic the natural extracellular matrix of muscle cells. This circumvents many limitations of previous approaches, such as reliance on rigid scaffolds and the need for complex microfabrication facilities.

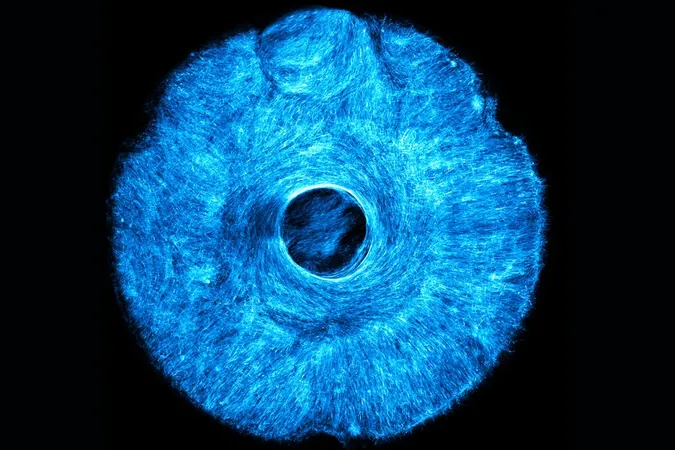

A Demonstration of Dynamic Motion: The Artificial Iris

To validate their groundbreaking method, the MIT team crafted an artificial iris using their STAMP technique. The human iris comprises two types of muscles—concentric fibers that control pupil constriction and radial fibers that enable dilation. By utilizing their specially designed stamp, they created a hydrogel environment where genetically engineered mouse muscle cells could flourish. As a result, the artificial iris could contract and expand in reaction to light, closely mimicking its natural counterpart’s behavior.

The implications of this advancement are vast; it brings forth the prospect of soft robots capable of intricate tasks that were previously unattainable, beyond simplistic movements like walking or gripping.

Implications for Medicine and Robotics

Beyond the realm of robotics, the capacity to mold muscle alignment in engineered tissues bears significant medical implications. The creation of accurate muscle models could transform drug testing, particularly for neuromuscular diseases where existing in-vitro models fall short. This new technology could provide more reliable results, accelerating the path to effective treatments.

Moreover, with muscle degeneration due to injury or aging becoming increasingly prevalent, bioengineered muscle tissues grown through STAMP could revolutionize reconstructive therapies, enabling restoration and rehabilitation of damaged muscle groups.

In the realm of soft robotics, the versatility of biohybrid robots powered by synthetic muscle tissue stands to offer solutions that are flexible, adaptable, and environmentally sustainable. Imagine underwater robots that, instead of rigid components, utilize soft biological muscles for enhanced navigation and energy efficiency.

A Bright Future Ahead

The potential applications of the STAMP method extend to an array of cell types, including neurons and cardiac muscle cells, illustrating a future rich with possibilities in bioelectronics and tissue engineering. The researchers are optimistic about democratizing this technique, noting that conventional 3D printers could also fabricate the necessary stamps, making it an accessible technology for researchers worldwide.

As Ritu Raman, a leader in the project, reflects, “We’re breaking through the limitations to create living machines that can do what earlier robotic forms could not. We envision a new age of biohybrid engineering.”

This MIT breakthrough not only signifies a monumental leap in creating artificial muscle tissues but also heralds a new era of medical advancements and intelligent robotic systems. As research advances, the incredible potential of bioengineering will likely continue to unfold, leading to innovations that blend the boundaries between biology and technology.

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

Česko (CS)

Česko (CS)

대한민국 (KO)

대한민국 (KO)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)

الإمارات العربية المتحدة (AR)

الإمارات العربية المتحدة (AR)