The Future of Medicine: Shape-Shifting Biomaterials Transforming Tissue Regeneration

2024-12-16

Author: William

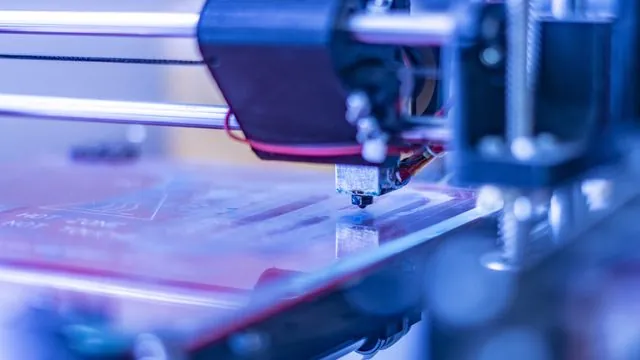

Imagine a world where medical devices could adapt and respond to your body just like living tissue. Inspired by the ingenious design of pinecones, a groundbreaking movement in biotechnology is reshaping the landscape of tissue regeneration. The principle behind this innovation is 4D printing—an advanced technique that revolutionizes how materials are created and utilized in medicine.

4D printing goes beyond traditional methods by incorporating the element of time as a fourth dimension. Just as a pinecone closes its scales when wet to protect its seeds and opens them in dry conditions for dispersal, 4D-printed materials dynamically adapt to stimuli such as temperature, humidity, and pressure. The applications of these shape-shifting biomaterials in healthcare are not only exhilarating but hold the promise of more effective and less invasive treatments.

A Paradigm Shift in Biomedical Applications

The versatility of 4D-printed materials facilitates the development of smart biomaterials that can autonomously change their shape in response to physiological needs. For instance, these materials can be crafted into deployable medical devices like stents that morph into a compact form during installation and expand once in the appropriate location inside the body. This transformation minimizes surgical intervention and leads to quicker recovery times for patients.

These innovations reach beyond structural functionality; they also introduce the potential for therapeutic surfaces. By employing complex nanopatterns and electronic components, 4D-printed scaffolds can actively stimulate cellular response, enhance healing, or even eliminate bacteria, paving the way for infection-resistant implants.

Layering Innovation for Enhanced Functionality

Amir Zadpoor, an expert at Delft University of Technology, highlights the transformative approach of creating scaffolds with multiple layers—each designed for different responses to environmental stimuli. By combining molecular materials with varying swelling capabilities, researchers can develop intricate structures that mimic natural tissues such as cartilage. One recent study successfully demonstrated this by creating a hydrogel scaffold that self-bends when exposed to liquid, promoting the growth of bone cells within its layers.

Dynamic Medical Solutions

The allure of 4D printing lies in its adaptability. For instance, custom stents designed to respond to internal body temperatures will adjust their configuration based on individual patient needs, potentially reducing the risk of complications and subsequent surgeries. Moreover, heart attacks have spurred the creation of specialized patches that can adapt to the beating of a heart, integrating seamlessly with the tissue to aid recovery.

Revolutionizing Drug Delivery

The advancements in shape-shifting biomaterials also open up innovative avenues for targeted drug delivery. Imagine small capsule-like robots designed to release medication at the precise moment and location required. Researchers are already testing concepts that involve magnetically controlled capsules capable of releasing their payload only when triggered by specific environmental factors, creating an unprecedented way to administer treatments that is less invasive and more efficient.

The Role of Artificial Intelligence

The integration of AI and machine learning is another revolutionary aspect of this field. Advanced algorithms can predict material behaviors based on external stimuli, enabling researchers to optimize the design of 4D materials for various applications in real-time. This future-forward approach allows for multi-material structures and the potential for sensors that monitor treatment responses continuously.

Challenges on the Path to Reality

Despite the excitement surrounding 4D printing technologies, significant hurdles remain before these innovations can make their way into clinical settings. The transition from laboratory research to scalable production necessitates robust testing and compliance with stringent regulatory standards. Each application in tissue engineering brings its unique challenges, underscoring the complexity of this pioneering work.

Nevertheless, experts like Zadpoor remain optimistic about the future of 4D-printed materials in medicine. As research continues to break new ground, we stand on the brink of a bioinspired revolution—paving the way for a future where our medical interventions are as dynamic and responsive as we are. Get ready for a healthcare transformation that’s about to change the way we think about healing forever!

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)