Breaking New Ground: Unraveling Performance Decline in High-Temperature Electrolysis Cells

2024-11-18

Author: Rajesh

Introduction

In a groundbreaking study, Dr. Hye Jung Chang and Dr. Kyung Joong Yoon, leading researchers at the Hydrogen Energy Materials Research Center of the Korea Institute of Science and Technology (KIST), have uncovered the critical mechanisms behind performance degradation in high-temperature solid oxide electrolysis cells (SOEC). Their innovative approach, utilizing cutting-edge transmission electron microscopy (TEM), has shed light on the initial stages of degradation that have largely eluded researchers in the past.

Nanoscale Focus

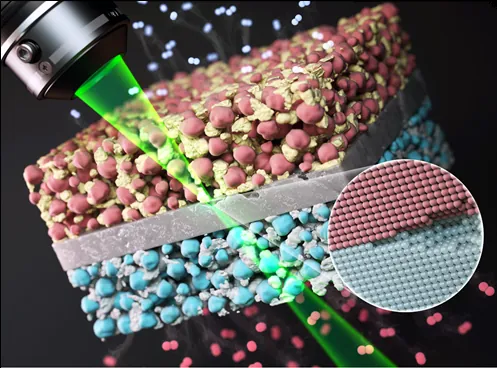

Traditionally, studies have focused on the latter stages of electrolysis cell failure, analyzing degradation at the micrometer scale. However, the KIST team shifted the lens to the nanoscale—detection sensitivity levels that truly unveil the early changes within the materials of electrolysis cells. They discovered that oxygen ions would accumulate at the interface of the electrolyte, specifically Yttria-Stabilized Zirconia (YSZ), during the oxygen injection phase essential for driving the electrolysis reaction.

Mechanisms of Degradation

This unique accumulation compresses the atomic structure of YSZ, leading to the creation of nanoscale defects and cracks at the interface between the air electrode and the electrolyte. These defects are the silent saboteurs of the cell's performance, gradually eroding efficiency over time. The researchers’ use of advanced TEM not only visualized these stresses and defects but also elucidated how they relate to the early stages of degradation, revealing a complex relationship between ions, atoms, and structural integrity.

Significance of the Research

What makes this research particularly significant is its potential to pave the way for enhanced durability and efficiency in commercial SOECs. By understanding the nanoscale degradation process, the team can spearhead the development of advanced materials that can maintain stable operations even at temperatures exceeding 600°C—achieving a substantial leap in the operational lifespan of electrolysis cells.

Industry Implications

The implications extend beyond academic curiosity. KIST's goal is to collaborate with industry players to accelerate the commercialization of these high-temperature electrolysis cells, particularly through the establishment of automated production processes. They are also focused on innovating new materials designed to mitigate the unwanted accumulation of oxygen ions within the cells, which could streamline production and reduce costs—the driving force behind economically viable clean hydrogen production.

Future Outlook

Dr. Chang expressed optimism about the future of hydrogen energy: "Using advanced transmission electron microscopy, we have identified the roots of previously misunderstood degradation phenomena at early stages. We aim to develop strategies that will boost the durability and efficiency of high-temperature electrolysis cells, vital for the economic viability of clean hydrogen production."

Conclusion

As we look to the horizon, this pioneering research heralds a new era in energy technology. With clean hydrogen gaining traction as a crucial player in the transition toward sustainable energy, KIST's findings could very well be the key to unlocking a more sustainable future. Stay tuned as we watch these innovations unfold!

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)