Breakthrough in Amino Acid Production: A Game Changer for the Environment!

2024-11-25

Author: Yu

Amino Acids: The Building Blocks of Life

Amino acids are often hailed as the "building blocks of life"—essential compounds that play a pivotal role in countless biological processes within the human body. From pharmaceuticals to dietary supplements, cosmetics, animal feed, and even industrial chemicals, amino acids are integral to a wide variety of products. However, the traditional methods of manufacturing these crucial compounds can be both costly and environmentally detrimental, often leading to the emission of greenhouse gases, like carbon dioxide (CO2).

A Revolutionary Method

A groundbreaking study has unveiled a revolutionary methodology for synthesizing amino acids that not only minimizes emissions but actually absorbs more carbon than it produces. Conducted by a team of innovators from Georgia Tech and esteemed collaborators, the research promises to pave the way for an eco-friendly and economically viable production system.

“It's a remarkable achievement that, to our knowledge, marks the first time amino acids have been synthesized in a carbon-negative manner utilizing this innovative type of biocatalyst,” asserts Pamela Peralta-Yahya, the study's lead corresponding author. This new system stands out not just for its efficiency, but also for its dual benefit: it provides a cost-effective feedstock by utilizing readily available carbon dioxide while simultaneously reducing one of the most potent greenhouse gases in our atmosphere.

Published in ACS Synthetic Biology, the study titled "Carbon Negative Synthesis of Amino Acids Using a Cell-Free-Based Biocatalyst" represents an impressive collaboration involving Georgia Tech, the University of Washington, Pacific Northwest National Laboratory, and the University of Minnesota.

Tackling the Amino Acid Production Dilemma

The challenge of synthesizing amino acids on an industrial scale has been twofold: high material costs and insufficient production speed. While certain microorganisms like cyanobacteria can produce amino acids from CO2, their output is often too slow for practical industrial processes, and they have a limited chemical synthesis capacity. Currently, most amino acids are generated by bioengineered microbes that convert sugar or plant biomass into valuable products. However, using sugar as a feedstock can compromise food resources, and processing plant biomass can be prohibitively expensive, all while contributing to CO2 emissions.

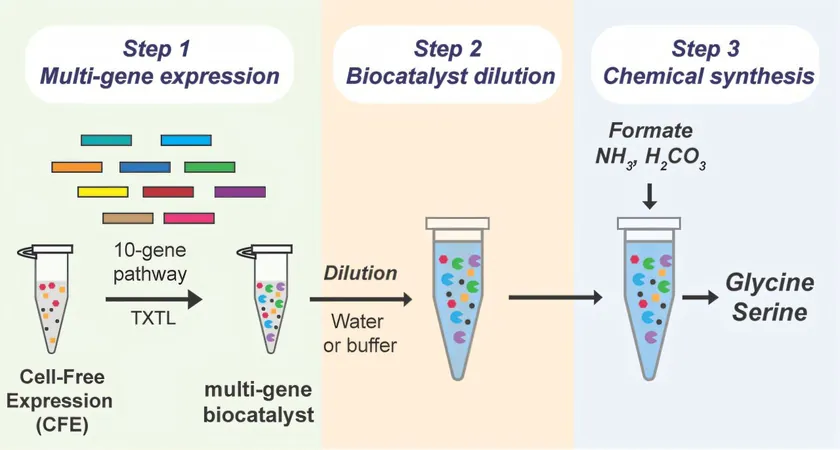

Chowdhury and his team were determined to explore the potential of a commercially viable system that directly used carbon dioxide. Their goal was to develop a process that could quickly and effectively convert CO2 into essential amino acids, such as glycine and serine, utilizing a method that does not rely on living cells.

The Power of a Cell-Free System

A significant innovation of this project is the use of a cell-free system, which harnesses cellular enzymes without the constraints of live cells. This allows for a higher yield of amino acids since the carbon used in the reaction isn't diverted to support cell growth, significantly amplifying production efficiency.

While cell-free systems have been employed before, the challenge remained with one critical component—the costly cell lysate biocatalyst. To ensure the system’s economic viability, the researchers focused on reducing the amount of this high-cost material required. By successfully creating a set of ten enzymes necessary for their reaction, they employed a technique known as volumetric expansion to dilute the biocatalyst.

"Our findings revealed that after being diluted 200-fold, the biocatalyst remained active," Peralta-Yahya points out. This essential discovery allows for reduced usage of expensive materials while simultaneously maximizing the output of amino acids.

A Greener Future Ahead

This novel approach to amino acid synthesis could mark a transformative moment not only in how essential compounds are produced but also in how this industry interacts with our environment amid the pressing challenges of climate change.

Peralta-Yahya envisions that this cutting-edge method could be extended beyond amino acids to manufacture a variety of chemicals—including aromatics, terpenes, alcohols, and polymers—reducing the sector's overall carbon footprint and potentially improving it.

In summary, this research heralds a new era of sustainable amino acid production, offering a glimpse into a future where industry and environmental stewardship go hand in hand. Could we soon see these innovations revolutionizing the way we produce countless essential compounds? The possibilities are boundless!

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)