Breakthrough in Wearable Tech: Ultra-Thin Film Harnesses Your Body Heat for Sustainable Power!

2024-12-16

Author: Li

Introduction

Exciting news from the Queensland University of Technology (QUT) in Brisbane, Australia! Researchers have unveiled a revolutionary ultra-thin, flexible film capable of converting body heat into energy, potentially marking the end of traditional battery reliance for next-generation wearable devices. This groundbreaking technology doesn’t just serve wearables; it could also cool electronic chips, significantly boosting the efficiency of our smartphones and computers.

A Vision of Eco-Friendly Wearables

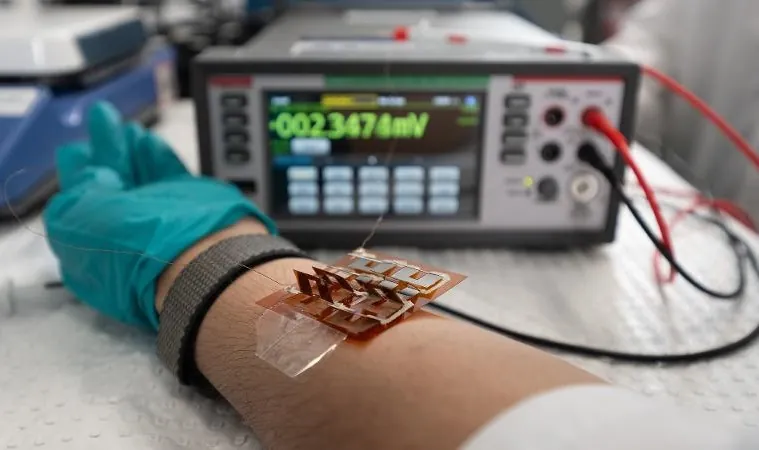

Imagine a world where your fitness tracker or smart band runs indefinitely on the heat generated by your own body — no batteries required! This innovation tackles a prevalent hurdle in the development of flexible thermoelectric devices that efficiently convert body heat into usable power. As wearable technology becomes more pervasive, this discovery heralds a new era of sustainable energy sources for electronics worn on the body.

A Breakthrough in Thermoelectrics

While much of the past research has centered around bismuth telluride-based thermoelectrics, renowned for their high efficiency, the QUT team has raised the bar with a novel, cost-effective approach. Their recent study, featured in the prestigious journal *Science*, details the use of tiny crystals, dubbed "nanobinders," which together create a seamless layer of bismuth telluride sheets. This advancement enhances both the efficiency and flexibility of these films, allowing for the creation of a printable A4-sized film that boasts record-breaking thermoelectric performance.

Production Techniques

Using a sophisticated "solvothermal synthesis" technique, where nanocrystals are created in a solvent under elevated temperature and pressure, combined with screen printing and sintering methods, the researchers have set the stage for large-scale production of these innovative films. The screen-printing process enables mass production, while the sintering method ensures that the particles are bonded together, delivering a product that is not only high-performing but also scalable and economical.

Future Implications

But that's not all! The researchers hinted at the possibility of extending this technique to other thermoelectric materials, such as silver selenide, which could yield even more sustainable and cost-efficient alternatives to conventional materials.

Conclusion

This breakthrough paves the way for a future where wearable technology is more sustainable and efficient than ever before. Stay tuned, as the implications of this innovation reach far beyond just wearables — it could redefine how we power devices in our tech-driven world!

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)