Breakthrough Nacre-Inspired Composite Promises Revolutionary Strength and Cost-Effective Manufacturing

2025-04-07

Author: Wei

Introduction

Mollusks have long fascinated scientists with the remarkable strength and durability of their shells, primarily attributed to the unique internal structure of nacre. This natural nanocomposite is celebrated for its exceptional mechanical properties, notably high strength and remarkable toughness, making it an ideal candidate for applications in lightweight structural materials and protective gear. Despite its potential, the widespread implementation of nacre-inspired materials has been hindered by issues like limited size, fabrication inefficiencies, and lack of design flexibility.

Breakthrough Research

However, recent research led by Academician Yu Shuhong at the University of Science and Technology of China (USTC) has unveiled a groundbreaking approach to creating nacre-like ceramic-metal composites, known as ceramets. These innovative materials are formed from deformable alumina microspheres coated in nickel salt and exhibit outstanding bending strength and fracture toughness. More excitingly, this new method allows for mass production in various shapes with ease.

Manufacturing Process

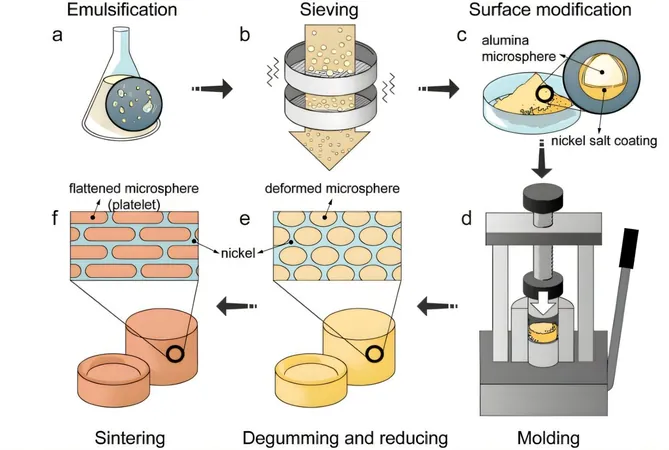

Published in the prestigious *National Science Review*, this pioneering research describes how the team synthesized alumina microspheres with precise size control through a process called emulsification of ceramic slurry in organic solvents. After achieving a uniform particle size through sieving, these microspheres were coated with a nickel salt layer. Utilizing mold assembly and hot-pressing techniques, the researchers transformed these coated microspheres into flat platelets. The nickel layer's strategic placement mimicked the natural nacre's intricate 'brick and mud' microstructure, resulting in a composite that mirrors the resilience of mollusk shells.

Versatile Production

One of the most striking features of this production method is its versatility. By varying the number of microspheres and employing irregular molds, the researchers can produce large and complex ceramets without the need for extensive additional processing.

Mechanical Properties

The results of this research are not only impressive on a macro scale, where layers of alumina and metallic nickel alternate, but also on a micro scale. Here, nickel particles intermingle with the ceramic, enhancing toughness while ensuring a robust bond at the interface of the two materials. Remarkably, this nacre-like material achieved a flexural strength of 386 MPa at room temperature, dropping only slightly to 286.86 MPa under intense heat at 600°C. Its fracture toughness scores were equally impressive, measuring 12.76 MPa·m¹/² at room temperature and 12.99 MPa·m¹/² at elevated temperatures.

Stress Testing and Applications

The research team observed that, during stress tests, when cracks formed in the nacre-like ceramets, they would redirect along the ceramic-metal interface. This characteristic prevents sudden failures by dissipating energy, hinting at the material's excellent potential for applications in extreme environments, including aerospace thermal protection and high-speed impact-resistant coatings.

Conclusion

This groundbreaking study signifies a significant advancement in the design of biologically inspired structural materials, paving the way for practical applications of composite materials that combine superior strength with cost-effective production methods. As industries continue to seek innovations that bolster safety and sustainability, nacre-like ceramets could soon become a fundamental part of our technological future.

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

Česko (CS)

Česko (CS)

대한민국 (KO)

대한민국 (KO)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)

الإمارات العربية المتحدة (AR)

الإمارات العربية المتحدة (AR)