ENNOVI Unleashes the Future of Pouch Cell Batteries with Revolutionary Design

2024-10-07

Author: Wei

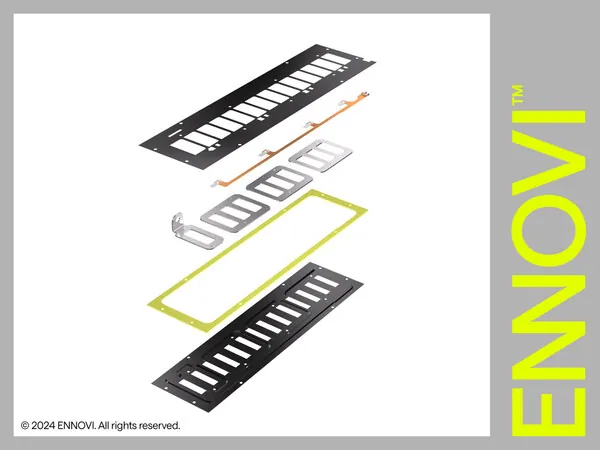

In a groundbreaking development for the electric vehicle (EV) industry, ENNOVI has announced the launch of its cutting-edge ENNOVI-CellConnect-Pouch, a sophisticated cell contacting system that aims to transform how pouch cell batteries are manufactured. This innovative solution enables battery manufacturers to streamline production significantly and enhance their operational efficiency.

Revolutionizing Production Efficiency

SINGAPORE, Oct. 7, 2024 — ENNOVI, a key player in the mobility electrification sector, is set to redefine battery manufacturing with its new ENNOVI-CellConnect-Pouch system. This system is specifically tailored for the pouch cell form factor, which is increasingly favored due to its lightweight and compact design. By integrating vertically organized production and precision processes, ENNOVI is not only lowering production costs but also simplifying logistics and reducing development time.

Gustavo Cibrian, Product Manager at ENNOVI, emphasized the advantages of this new system, stating, “With our ENNOVI-CellConnect-Pouch, we deliver a fully integrated production solution that drastically lowers cycle times through hot lamination processes, removing the need for cumbersome plastic cell carriers typically made from glass-reinforced materials. This innovation eliminates costly carrier storage, molding lines, and the heat staking process, enabling a more efficient workflow.”

Safety and Sustainability at the Forefront

One of the standout features of the ENNOVI-CellConnect-Pouch is its advanced lamination technology, which enhances the durability and structural integrity of battery packs. Unlike traditional methods, this system employs flexible die-cut circuit (FDC) technology for low voltage signal traces. This not only reduces manufacturing costs but also emphasizes environmental considerations by minimizing waste.

The design incorporates an upper dielectric layer with integrated FDC copper traces and a lower layer shaped to fit current collectors perfectly. Both layers utilize high-quality automotive-grade polyimide (PI) or polyethylene terephthalate (PET) materials, ensuring excellent electrical insulation and temperature stability. Importantly, the design includes built-in safety features such as fuse traces and NTC temperature sensors. This configuration promotes fast gas exhaust release during thermal events, significantly mitigating the risk of battery thermal runaway.

Impact on the EV Market

As the demand for sustainable energy solutions continues to rise, innovations such as the ENNOVI-CellConnect-Pouch are poised to play a crucial role in the evolution of electric vehicles. By offering manufacturers a streamlined, cost-effective, and safer alternative to existing technologies, ENNOVI is helping to accelerate the shift towards electrification in the automotive industry.

For further insights and details about the ENNOVI-CellConnect-Pouch system, visit ENNOVI's official website.

As the electric vehicle market thrives, technologies like ENNOVI’s will undoubtedly be at the forefront, shaping the future of mobility and making advanced battery solutions more accessible and efficient. Stay tuned for more updates on how industry leaders are innovating to meet the demands of a greener tomorrow.

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)