EU's Bold Move to Secure Rare Earth Supply as EV Market Surges – Are They Ready for the Challenge?

2024-11-20

Author: Siti

As the global electric vehicle (EV) market accelerates at an unprecedented pace, the demand for rare earth minerals essential for EV batteries is skyrocketing. This surge in demand has sparked alarm bells in Europe, where policymakers worry about an over-reliance on China, which dominates the market, controlling over two-thirds of the world’s production of these crucial materials.

Rare earth minerals—like lithium, cobalt, and nickel—are critical not only for electric vehicles but also for renewable energy technologies, including wind turbines. With the green energy transition gaining momentum, the demand for these minerals is projected to multiply, prompting the European Union (EU) to take significant action.

Ambitious Recycling Goals: A Game Changer?

In a bid to fortify its domestic supply chain, the EU has set ambitious targets to ensure that by 2030, a significant 25% of its rare earth mineral requirement comes from recycling. Currently, a mere 1% of these precious materials used in the EU is recycled.

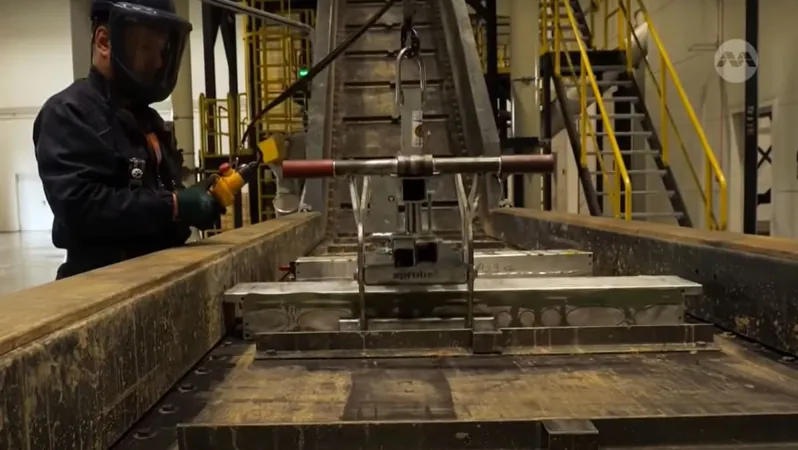

This challenge is being met with innovation down in southern Poland, where a pivotal joint venture, AE Elemental, is emerging. This collaboration between Poland’s Elemental Strategic Metals and the U.S. firm Ascend Elements is already making waves. Their new multimillion-dollar metals-processing plant in Zawiercie aims to recycle up to 12,000 tonnes of EV batteries annually—equivalent to the batteries needed for approximately 28,000 electric vehicles.

Maciej Dudzic, a board member at Elemental Strategic Metals, highlighted the urgent need to bridge the widening gap between supply and demand in the European market. The plant employs advanced techniques to recycle batteries by crushing them into what’s known as ‘black mass,’ from which lithium and other valuable materials can be reclaimed and reused.

And there’s more on the horizon—by 2026, another plant will be operational on the same site, specifically focused on lithium extraction from black mass, with the capacity to process 20,000 tonnes of material each year. Dudzic confidently stated, "More than 90% of the battery's mass waste is recovered and transformed into valuable raw materials."

Navigating Dependency Risk with New Legislation

The EU is acutely aware of the perils associated with relying on imports, especially from China, which can supply up to 100% of certain critical raw materials needed by the bloc. In response, the EU enacted the Critical Raw Materials Act, effective since May, mandating that by 2030, 10% of rare earth minerals used in the EU must be mined domestically. Moreover, it aims for at least 40% of these materials to be processed within EU borders, and a minimum of 15% to be recycled.

However, experts are cautioning that this ambitious roadmap may face considerable hurdles. Raimund Bleischwitz, a professor at the University of Bremen, warned that while targets exist, there’s a significant gap in actionable policy that would ensure success. "What policymakers provide is a plan, but businesses need proactive measures, like a quota for new products to contain recycled materials," he stressed.

With global climate goals increasingly focusing on transitioning from combustion engines to electric vehicles, securing a steady supply of rare earth metals is critical. This is not just about energy transition; it’s about meeting net-zero emissions targets while ensuring that Europe does not find itself at the mercy of external suppliers.

As the race heats up, will the EU be able to pivot quickly enough to safeguard its future in the electric vehicle market? Only time will tell. The stakes are high, and every scrap of rare earth metal could be the key to securing a greener, more sustainable future. Stay tuned as this story unfolds!

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)