Revolutionary Bacterial Cellulose Macrofibers: A Game-Changer in Eco-Friendly Material Science!

2024-10-07

Author: John Tan

Introduction

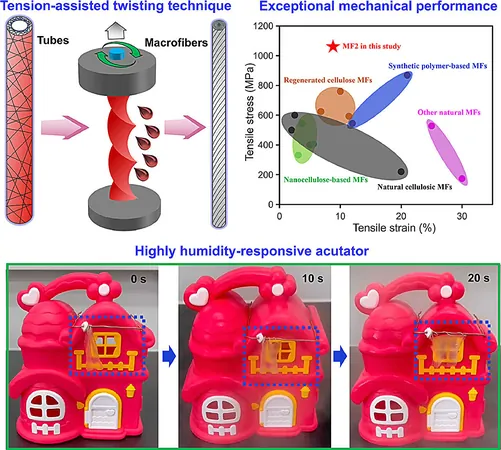

In an exhilarating breakthrough for sustainable materials, researchers have unveiled a groundbreaking tension-assisted twisting (TAT) method that fabricates super-strong bacterial cellulose (BC) macrofibers with extraordinary strength and moisture responsiveness. This astonishing development opens up new realms for eco-friendly advanced materials and is documented in the esteemed Journal of Bioresources and Bioproducts.

Research Team and Methodology

A collaborative team of international researchers, spearheaded by experts Yadong Zhao and Zheng Yang from Zhejiang Ocean University, alongside scholars from Xi'an Jiaotong University and the University of Sydney, has introduced this innovative TAT technique. It artfully aligns BC nanofibers into macrofibers (MFs) exhibiting remarkable mechanical properties, including impressive tensile strength and elasticity.

The TAT Technique

The TAT technique involves stretching and aligning pre-arranged BC nanofibers in hydrogel tubes, forming MFs that boast compact structures and enhanced hydrogen bonding between fibers. This revolutionary approach achieves an astonishing tensile strength of 1,057 MPa, making these MFs some of the strongest available. Additionally, their moisture-responsive nature allows them to exhibit rapid actuation under varying humidity levels—with a staggering peak rotation speed of 884 revolutions per minute per meter.

Performance Capabilities

Unmatched by most cellulose-based macrofibers, the newly engineered BC MFs display extraordinary lifting capabilities, with the thinnest strand capable of lifting over 340,000 times its own weight! Such performance is a remarkable feat within the material science field and opens the door to numerous applications.

Practical Implications and Applications

The practical implications of this research could reshape industries far beyond traditional uses. The humidity-responsive actuation means these fibers could efficiently serve as intelligent switches, remote rain indicators, and even smart curtains. Their unique ability to twist and untwist in response to water vapor, returning to their original state after drying off, positions them as pioneers for moisture-triggered devices that could enhance our daily lives.

Conclusion

This study reaches a compelling conclusion: the TAT technique is not only feasible for manufacturing high-performance MFs but also provides a vital pathway toward sustainable practices in material production. Such advancements are instrumental as the global community increasingly prioritizes environmental sustainability and the transition to renewable materials in various industries.

Future Prospects

As researchers continue to explore the vast potential of bacterial cellulose, the future of material science looks promising, with eco-friendly innovations set to revolutionize the market! Keep an eye out for potential applications; the dawn of bio-based materials is here!

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)