Revolutionary Breakthrough in Self-Sensing Materials: Could This Change How We Build Our World?

2024-10-07

Author: Rajesh

Revolutionary Breakthrough in Self-Sensing Materials: Could This Change How We Build Our World?

Recent advancements in materials science have introduced a groundbreaking system that promises to reshape our approach to 3D-printed materials, enabling the creation of innovative self-sensing technologies that could revolutionize industries like aerospace, automotive, and civil engineering.

A team of engineers from the University of Glasgow, led by Professor Shanmugam Kumar from the James Watt School of Engineering, has successfully developed a sophisticated modeling system that accurately predicts the complex behaviors of 3D-printed composite materials. This technology allows for the detection of strain, load, and damage through simple electrical current measurements—eliminating much of the guesswork that has historically hindered material science.

The significance of this development cannot be overstated. For industries where safety is paramount, such as aerospace and automotive, these advanced materials provide a way to monitor structural integrity in real time. This capacity for continuous assessment not only enhances safety but also increases maintenance efficiency, potentially saving lives and substantial financial resources.

In the realm of civil engineering, the implications are no less transformative. The ability to monitor the structural health of critical infrastructure—like bridges, tunnels, and high-rise buildings—may allow engineers to identify potential weaknesses long before catastrophic failures occur. This proactive approach to maintenance could make our cities safer and more resilient against natural disasters.

The research hinges on the principles of 3D printing, or additive manufacturing, which constructs objects layer by layer using diverse materials, including plastics and metals. The introduction of honeycomb-like structures within these materials can create an optimal balance between weight and strength.

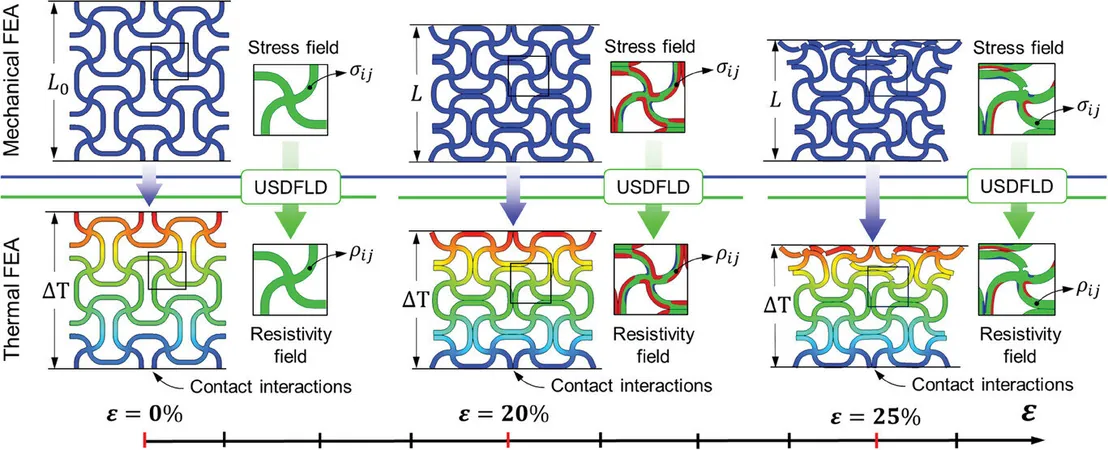

A key innovation is the incorporation of carbon nanotubes throughout the material, which not only enhance structural integrity but also imbue it with piezoresistivity—the ability to self-monitor through real-time changes in electrical resistance. When the material experiences stress or strain, a corresponding change in electrical current offers immediate insight into the material's condition.

Professor Kumar emphasized the far-reaching potential of their findings, stating, “By providing a method to predict how new self-sensing materials perform, we remove the inefficiencies of trial and error. This could lead to the widespread adoption of these autonomous sensing materials across multiple fields, from manufacturing to military applications.”

As part of their research, the team employed a polymer known as polyetherimide (PEI) enhanced with carbon nanotubes. They designed a series of four different lightweight lattice structures, rigorously testing them for performance attributes such as stiffness, strength, and self-sensing capabilities. Their predictive model, grounded in extensive experimental data, showed remarkable accuracy in forecasting material responses to various stress and strain scenarios.

Additionally, advanced imaging techniques, such as infrared thermal imaging, were utilized to visualize the flow of electrical current through the materials, revealing insights into their performance under practical conditions.

This research builds on previous work by the team and represents a significant leap forward in our understanding of additive manufacturing. With the foundational knowledge garnered from these experiments, researchers hope to inspire a new wave of innovation in self-sensing materials, paving the way for safer, smarter infrastructure and products.

As industries worldwide begin to harness the power of these autonomous sensing materials, the possibilities are endless. From ensuring the reliability of our everyday vehicles to enhancing the durability and safety of critical infrastructure, this breakthrough promises to bring us one step closer to a high-tech future where materials work as smart agents, continuously monitoring their own health and functionality.

Keep an eye on this space—these advanced materials could very well change the way we interact with the built environment for generations to come!

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)