Revolutionary Discovery: High-Temperature CO2 Capture Could Transform Industrial Emissions Control!

2024-11-19

Author: Jia

Introduction

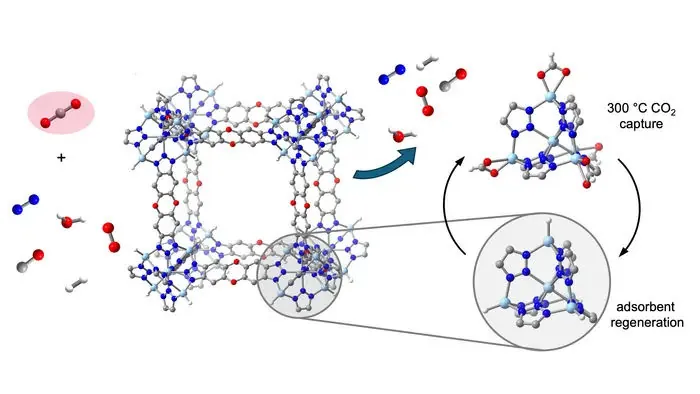

In an exciting development, chemists at the University of California, Berkeley, have unveiled a groundbreaking material that acts like a sponge for capturing carbon dioxide (CO2) from hot industrial exhaust streams. This innovative material, a specific type of metal-organic framework (MOF), will be detailed in an upcoming paper set to be published on November 15 in the prestigious journal *Science*.

The Challenge of Carbon Capture

Traditionally, capturing carbon from industrial emissions involved using liquid amines, which only work efficiently at relatively cool temperatures between 40 and 60 degrees Celsius (100-140 degrees Fahrenheit). However, many industrial processes, such as cement and steel manufacturing, emit exhaust at extreme temperatures—often exceeding 200 degrees Celsius (400 degrees Fahrenheit) and reaching up to 500 degrees Celsius (930 degrees Fahrenheit). Current technologies are inadequate at these high temperatures, with new materials being developed that either break down or operate inefficiently past 150 degrees Celsius (300 degrees Fahrenheit).

A Paradigm Shift in CO2 Capture

Postdoctoral fellow Kurtis Carsch, a co-author of the study, emphasized the financial burden of cooling these hot gas streams before they can be processed. "Our finding represents a paradigm shift for carbon capture. We have demonstrated that this MOF can efficiently capture CO2 at significantly higher temperatures than previously thought feasible," he stated.

Characteristics of the New MOF

Co-author Rachel Rohde, a graduate student at UC Berkeley, added, "We are breaking away from the common focus on amine-based capture systems and presenting an alternative method that allows for high-temperature operation."

This newly discovered MOF features a porous and crystalline structure with a staggering internal surface area equivalent to six football fields per tablespoon—this vast surface area is crucial for absorbing gases. The unique architecture of MOFs provides numerous sites for CO2 capture and release under the right conditions.

Efficiency in Capturing CO2

Under controlled laboratory conditions, researchers demonstrated that this new MOF could effectively capture up to 30% of CO2, which is highly relevant for industrial emissions from processes that average 20% to 30% CO2 content, like cement and steel production. It can also manage less concentrated emissions from natural gas power plants, which typically contain about 4% CO2.

Importance for Climate Change

This advancement is vital for reducing greenhouse gas emissions contributing to climate change. While renewable energy sources continue to grow, hard-to-decarbonize industries like steel and cement will require innovative solutions like this high-temperature CO2 capture method to mitigate their emissions.

Research and Development

The research team, led by Professor Jeffrey Long, has been at the forefront of CO2 capture technologies for over a decade. Previous efforts yielded promising results, but the incorporation of zinc hydride sites into this new MOF has made it remarkably stable, enabling a "deep carbon capture" capability—allowing it to capture over 90% of the CO2 it encounters.

Reusability of the MOF

What's even more interesting is that once saturated with CO2, the MOF can release the greenhouse gas by adjusting the pressure, making it reusable for multiple cycles. "This breakthrough defies conventional wisdom about gas separation at high temperatures," says Professor Long. "With the right design, we've shown that effective CO2 capture is possible even at temperatures as high as 300 degrees Celsius."

Future Prospects

As research continues, Rohde and her colleagues are exploring variations of this MOF to capture other gases and enhance its CO2 adsorption capability. This pioneering work opens the door for the development of functional adsorbents that can effectively operate in high-temperature industrial settings, potentially revolutionizing carbon capture technology and contributing to global sustainability efforts.

Conclusion

Stay tuned for more on how this incredible discovery could reshape the future of industrial emissions management!

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)