Revolutionary Discovery: Scientists Unravel a 200-Year-Old Conundrum in Polymer Science!

2024-11-28

Author: Mei

Revolutionary Discovery: Scientists Unravel a 200-Year-Old Conundrum in Polymer Science!

In a groundbreaking development, researchers at the University of Virginia’s School of Engineering and Applied Science have shattered conventional wisdom in polymer engineering. No longer does the adage hold true that increased stiffness in polymeric materials necessitates a reduction in stretchability.

“We are tackling a fundamental problem that has evaded solutions since the inception of vulcanized rubber in 1839,” stated Liheng Cai, an assistant professor specializing in materials science and chemical engineering. This pivotal moment traces back to when Charles Goodyear stumbled upon the transformative chemical crosslinking process that converts natural rubber into a robust, elastic material when heated with sulfur.

For over two centuries, it was accepted that achieving stiffness in polymer networks would invariably compromise their ability to stretch. However, Liheng Cai’s team, guided by Ph.D. student Baiqiang Huang, has introduced an innovative polymer design termed “foldable bottlebrush polymer networks,” challenging this long-standing paradigm. Their remarkable research, supported by Cai’s National Science Foundation CAREER Award, has garnered attention and is featured on the cover of the upcoming issue of Science Advances.

The Breakthrough: Separating Stiffness from Stretchability

“This limitation has stunted the advancement of materials that must possess both attributes—stiffness and stretchability—forcing engineers to compromise,” Huang explained. Picture a heart implant designed to flex with each heartbeat while lasting for years; this is just one application their discovery could enhance.

Crosslinked polymers are ubiquitous in everyday products, ranging from automobile tires to electronic devices, and are increasingly vital in medical technologies. Applications for the newfound material are extensive, with prospects including prosthetics, advanced medical implants, and “muscles” for soft robotics, emphasizing the need for durability and flexibility in these designs.

Traditionally, stiffness and extensibility—properties pertaining to a material's ability to stretch or twist without breaking—stem from the same polymer strands linked by crosslinks. Increasing crosslinks traditionally stiffens a polymer but sacrifices flexibility, leading to a trade-off that has hindered technological progress.

Cai's team broke this barrier by innovatively designing bottlebrush polymers that can store additional lengths within their structure, effectively “decoupling” stiffness and stretchability. “Our approach emphasizes the molecular design of the strands, rather than focusing solely on crosslinks,” Cai elucidated.

The Ingenious Foldable Design Explained

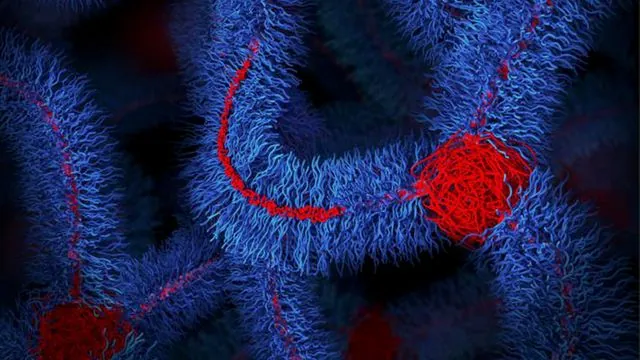

Unlike standard linear polymers, Cai’s design mimics a bottlebrush, incorporating multiple flexible side chains extending from a central backbone. This strategic design allows the backbone to function like an accordion, expanding and collapsing as needed. When the material is stretched, internal lengths within the polymer can release and uncoil—enabling it to elongate up to 40 times more than conventional polymers without loss of strength.

Critically, this design paradigm permits independent control over stiffness (determined by the side chains) and stretchability, marking a notable advancement in polymer science.

Importantly, this strategy is “universal,” applicable to various chemical types within the polymer structure. For instance, one design utilizes a polymer that retains flexibility even in frigid conditions, while others might employ synthetic polymers effective in biomaterial engineering—potentially producing gels that mimic biological tissues.

Moreover, akin to other pioneering materials emerging from Cai's lab, these foldable bottlebrush polymers can be 3D-printed, even when combined with inorganic nanoparticles. These inclusions can be engineered to possess unique electric, magnetic, or optical properties crucial for developing next-generation wearable and stretchable electronics.

“The combination of these components offers limitless possibilities for crafting materials that harmonize strength and flexibility, all while harnessing the advantageous properties of inorganic nanoparticles tailored for specific applications,” Cai asserted.

This groundbreaking discovery could revolutionize how polymers are utilized across various industries, opening the door to a new era of materials science where flexibility and stiffness coexist in harmony. What other challenges will researchers tackle next? Only time will tell!

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)