Revolutionary New Filter Promises to Turn Aluminum Manufacturing Waste into Reusable Resources

2025-01-07

Author: Jia

In a world increasingly reliant on aluminum—from the soda cans we drink from to essential components in technology and aerospace—the push for sustainable production methods becomes more critical than ever. Currently, aluminum is the second-most-produced metal globally, only behind steel, and demand is projected to soar an astonishing 40% by the end of this decade. However, this growth carries significant environmental repercussions, as the manufacturing process produces a trove of hazardous waste.

In response to these environmental challenges, engineers at MIT have developed a groundbreaking nanofiltration technology aimed at capturing and recycling aluminum from the waste generated during its production. This innovative process could potentially transform the way aluminum plants operate, allowing them to reclaim aluminum ions that would otherwise contaminate effluent streams. By capturing this aluminum, plants could enhance their production yields while minimizing waste and lowering their ecological footprint.

In laboratory tests, MIT's new membrane technology demonstrated its prowess by successfully filtering solutions that mimic the waste produced by aluminum manufacturing. Impressively, the membrane achieved a selective capture rate of over 99% of aluminum ions from these waste solutions, showcasing its potential to drastically reduce industrial waste.

John Lienhard, the Abdul Latif Jameel Professor of Water at MIT, highlighted the dual benefits of this technology: “Not only does this membrane technology mitigate hazardous waste, but it also enables a circular economy for aluminum by reducing the demand for new mining.” This innovative approach is positioned as a promising solution to address urgent environmental concerns while satisfying the growing global demand for aluminum.

The study detailing this breakthrough is published in the prestigious journal, ACS Sustainable Chemistry and Engineering, and features contributions from both undergraduate and graduate researchers at MIT.

The Aluminum Production Process and Its Waste Challenges

Aluminum production begins with the mining of bauxite, a metal-rich ore. The extraction process involves complex chemical reactions to isolate aluminum from the surrounding rock, leading to the production of aluminum oxide, also known as alumina. This substance is then transported to refineries, where it undergoes electrolysis—a high-energy process that separates aluminum from oxygen. Yet, as this method progresses, a byproduct known as cryolite accumulates impurities that diminish its effectiveness, ultimately leading to waste.

Trent Lee, the study's lead author, revealed the stark reality: “For a traditional aluminum plant, approximately 2,800 tons of aluminum are wasted each year.” Recognizing this inefficiency, the MIT team set out to find effective recycling methods, as cryolite waste remained largely underexplored in terms of potential recovery options.

Harnessing Membrane Technology for Sustainable Practices

To address these challenges, the MIT researchers designed a membrane that selectively captures aluminum ions while allowing other ions—particularly sodium—to pass through. Using advanced membrane technology, which has been adapted from conventional water treatment processes, the new approach features a modified surface charged positively to effectively retain aluminum while facilitating the passage of lesser-charged ions.

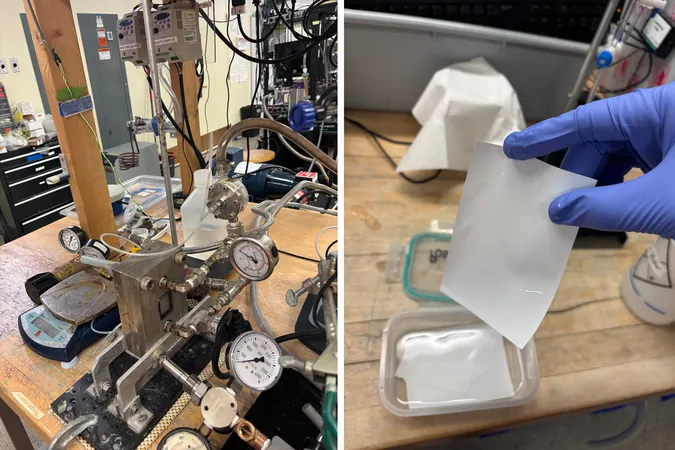

In collaboration with the Japanese membrane company Nitto Denko, the team evaluated existing commercial membranes to determine their efficacy in filtering cryolite wastewater. Their innovative design succeeded in consistently recovering 99.5% of aluminum ions under various pH conditions, effectively demonstrating versatility even in challenging environments.

The experimental membrane is compact, measuring about the size of a playing card. The researchers envision scaling this technology for industrial use by employing a spiral design akin to that used in desalination processes, allowing for large volumes of wastewater treatment.

A Step Towards a Sustainable Future

“With this study, we demonstrate that membrane technologies hold tremendous potential for advancements in circular economies,” says Lee, noting that this innovation not only helps recycle aluminum but also eliminates the hazardous waste associated with its production. In an era of heightened awareness about sustainability and resource management, MIT's cutting-edge research signifies a monumental leap in transforming aluminum manufacturing into a more sustainable and efficient industry.

This breakthrough could indeed mark a turning point in how we view industrial waste, paving the way for a cleaner and greener future in aluminum production. The broader implications of such technologies could resonate across various industries, prompting a shift towards more responsible resource management practices.

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

Česko (CS)

Česko (CS)

대한민국 (KO)

대한민국 (KO)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)

الإمارات العربية المتحدة (AR)

الإمارات العربية المتحدة (AR)