Revolutionary Spray Drying Technique Achieves Unprecedented 98% Active Material in Battery Components!

2025-04-09

Author: Mei

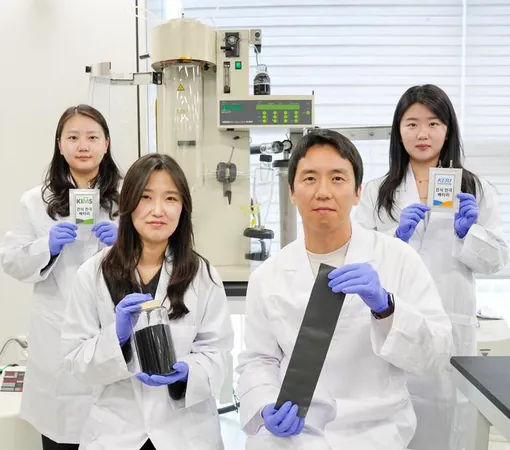

Imagine a world where the process that transforms your morning coffee into instant granules is now fueling the next generation of energy storage solutions. Researchers from the Korea Electrotechnology Research Institute (KERI) and the Korea Institute of Materials Science (KIMS) have ingeniously adapted spray drying—a method widely used in the food industry—to manufacture high-capacity battery electrodes. This groundbreaking research addresses significant challenges in battery production and paves the way for greener manufacturing practices.

The Environmental Edge

One of the most impressive aspects of this new process is its environmental advantages. Traditional battery manufacturing methods, specifically the “wet” slurry-casting approach, require mixing active materials with solvents. This process consumes about 27% of total manufacturing energy for drying and often involves harmful solvents like N-methyl-2-pyrrolidinone (NMP), which necessitates expensive recovery systems and adds approximately 4.6% to production costs. Moreover, this traditional method faces challenges such as "binder migration" during drying, complicating the creation of thicker electrodes required for enhanced energy density.

The dry processing method proposed by KERI and KIMS eliminates the need for toxic solvents and drying energy costs. By achieving thicker electrodes, they enable a greater concentration of active materials, which is crucial for enhancing battery performance. However, achieving a uniform mixture of components in dry processing has posed its own challenges, as conductive additives like carbon nanotubes tend to clump together.

Innovative Solution: Spray Drying

The KERI-KIMS team has introduced the spray drying technique to overcome these issues. This method, already familiar in the food sector for producing instant coffee, involves atomizing a liquid mixture into a high-temperature chamber where the solvent evaporates rapidly, resulting in a homogenous powder. Here’s an overview of their innovative approach:

1. **Material Premixing:** The researchers first combined the lithium nickel cobalt manganese oxide (LiNi0.8Co0.1Mn0.1O2, or NCM811) with single-walled carbon nanotubes (SWCNTs) to form a liquid slurry.

2. **Spray Drying:** This slurry is then atomized into a heated chamber at around 210°C, quickly evaporating the liquid and generating a uniform composite powder, referred to as SW-SPD in their studies.

3. **Dry Electrode Formation:** The resulting powder is mixed with a polytetrafluoroethylene (PTFE) binder, followed by a specialized process called "fibrillation," where the binder is elongated into thread-like structures to cohesively integrate the components.

4. **Calendering:** Finally, the mixture is pressed into a thin, dense electrode film, ready for integration into battery systems.

This new dry process completely avoids the use of NMP, substantially lowering the energy consumption and environmental impact of electrode manufacturing.

Outstanding Results

The implications of this solvent-free method are staggering. The researchers achieved a remarkable 98% active material content in the final electrode, a record in the field. This reduction in non-storage components like conductive additives—practically dropping from the typical 2-5% down to just 0.12%—means more space for active materials, directly enhancing energy storage potential.

As a result, the dry electrodes produced exhibit an extraordinary areal capacity of around 7 mAh/cm², effectively doubling the performance of conventional electrodes, which typically range from 2-4 mAh/cm². The research also confirms impressive cycle stability, with the electrodes maintaining 89.4% of their capacity after 100 cycles and 52.2% after 500 cycles, even under high-capacity loads.

The Future of Energy Storage

This novel spray drying technique not only signifies a major breakthrough in battery production but also sets the stage for developing next-generation batteries that could revolutionize energy storage technologies. As the world shifts towards greener solutions, findings like those from KERI and KIMS will play a crucial role in crafting sustainable energy systems for the future. Keep your eyes on this space—it could redefine how we approach energy storage and consumption!

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

Česko (CS)

Česko (CS)

대한민국 (KO)

대한민국 (KO)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)

الإمارات العربية المتحدة (AR)

الإمارات العربية المتحدة (AR)