Revolutionary Technique Unlocks Mass Production of SiO₂ Multi-Shell Hollow Spheres: The Future of Advanced Materials!

2024-11-19

Author: Li

Introduction

In a groundbreaking advance for materials science, SiO₂ multi-shell hollow spheres (MHSs) are making waves in various applications due to their unique properties, including porous walls and empty spaces. These innovative structures are poised to revolutionize fields ranging from confinement catalysis and energy storage to chemical separation and drug delivery. Yet, the leap from small-scale laboratory production to large-scale industrial manufacturing presents significant challenges.

Novel Precursor Hydrolysis Method (PHM)

To tackle this issue, a team of pioneering researchers led by Prof. Zhu Qingshan from the Institute of Process Engineering (IPE) at the Chinese Academy of Sciences has unleashed a novel precursor hydrolysis method (PHM) that enables the mass production of SiO₂ MHSs easily. Their promising findings have been detailed in the esteemed journal, Advanced Materials.

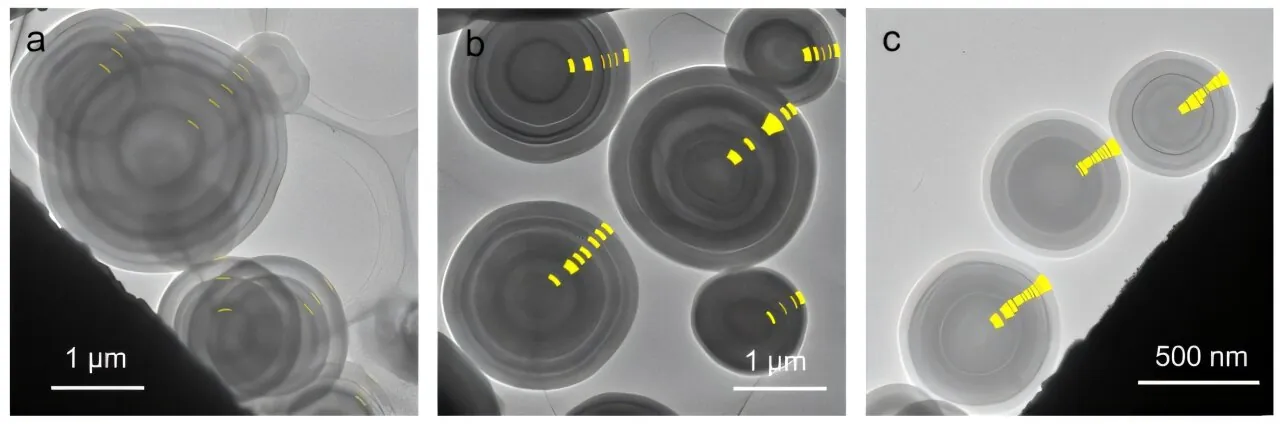

Synthesis Process

The inventive process begins with the synthesis of precursors containing Si(NH)₂, derived from the chemical reaction of SiCl₄ with NH₃ in a specialized fluidized bed reactor. This is followed by hydrolyzing the precursors in ammonia water at a controlled temperature of 25°C for five hours, which sets the stage for the formation of the desired SiO₂ MHSs as they are heated to 60°C.

Characteristics and Flexibility

A standout feature of this research is the ability to finely tune the characteristics of the SiO₂ MHSs. By adjusting the hydrolysis medium, the team has successfully controlled the void ratios and diameters of these spheres, achieving void ratios between 0.05 and 0.85. This flexibility is vital for tailoring the materials for specific applications in energy systems and pharmaceuticals.

Implications for the Future

The implications of this research are profound. The scalable production of SiO₂ MHSs opens up exciting new avenues in nano-technology, allowing for improved catalysts that could lead to reduced energy consumption in various chemical processes. As industries shift towards more sustainable and efficient practices, the demand for such advanced materials is expected to skyrocket.

Conclusion

Stay tuned for more updates, as this revolutionary method could forge the pathway to a new era of material applications that influence daily life across the globe!

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)