Revolutionizing Energy Storage: The Future of Lithium-Sulfur Batteries with Single-Step Laser Printing

2025-04-23

Author: Li

The Groundbreaking Technique Changing Battery Manufacturing

A visionary research team has unveiled a cutting-edge, single-step laser printing technique that promises to reshape the manufacturing of high-performance lithium-sulfur batteries. This breakthrough, spearheaded by Prof. Mitch Li Guijun at the Hong Kong University of Science and Technology (HKUST), integrates the often tedious processes of active material synthesis and cathode preparation into a lightning-fast laser-induced conversion. This could be the turning point for the mass production of next-generation electrochemical energy storage devices.

Why Lithium-Sulfur Batteries are the Future

Lithium-sulfur batteries are poised to outperform traditional lithium-ion batteries, thanks to the high energy density of sulfur cathodes. However, the current methods of producing these batteries are riddled with complexity and inefficiency, often involving multiple steps that vary in temperature and require labor-intensive efforts. With rising demands for faster, cheaper battery production, this new approach couldn't come at a better time.

Streamlining the Process with Laser Technology

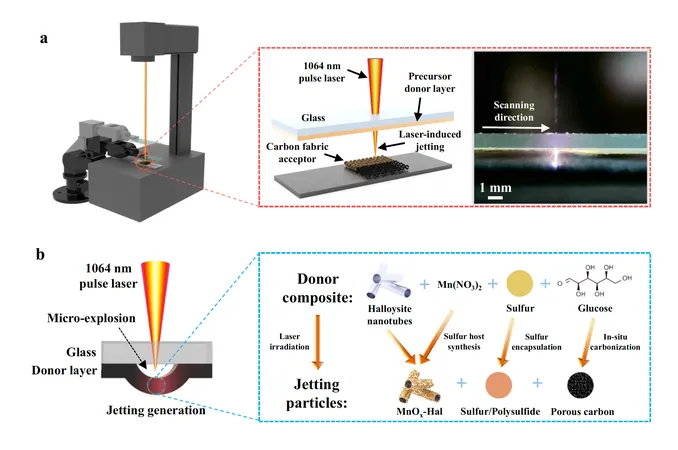

Prof. Li's innovative technique simplifies the manufacturing of sulfur cathodes by using a high-throughput laser process. This rapid laser-pulse method activates precursor materials, resulting in jetting particles that include halloysite-based hybrid nanotubes, sulfur, and glucose-derived porous carbon—all crucial for creating a robust sulfur cathode. The integration of these materials occurs seamlessly as the mixture is printed onto a carbon fabric, yielding remarkable results in both coin and pouch lithium-sulfur cells.

Fast and Efficient: The Future is Here

"Traditional methods of battery manufacturing involve various time-consuming steps that can stretch for hours or even days," noted Prof. Li. With the new laser-induced technology, the entire process is condensed into a single operation executing at nanosecond speeds. Impressively, this technique can achieve a printing speed of around 2 cm² per minute, allowing for the fabrication of a 75 x 45 mm² sulfur cathode within just 20 minutes—a feat that can power a small screen for several hours in a lithium-sulfur pouch cell.

The Science Behind the Innovation

Dr. Yang Rongliang, the lead author of the study, highlighted the unique characteristics of the laser-induced conversion process, describing it as an ultra-concentrated thermal phenomenon. The materials experience rapid heating and cooling, with temperatures soaring to thousands of degrees Kelvin, leading to a decomposition and recombination that creates new materials. This intense thermal process not only facilitates the fusion of varied material types but also triggers micro-explosions, enhancing the jetting of forming particles for optimal cathode performance.

A Game Changer for the Battery Industry

The implications of this technological advancement could be monumental for the energy storage sector. As industries strive for more efficient, eco-friendly, and cost-effective solutions, this single-step laser printing technique could herald a new era in battery manufacturing, making the dream of high-performance, sustainable energy storage devices a reality.

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

Česko (CS)

Česko (CS)

대한민국 (KO)

대한민국 (KO)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)

الإمارات العربية المتحدة (AR)

الإمارات العربية المتحدة (AR)