Revolutionizing Fashion: The Groundbreaking Visual Grading System to Tackle Microplastic Pollution

2024-11-19

Author: Rajesh

In a startling revelation, over 14 million metric tons of microplastics are currently estimated to be resting silently on the ocean floor, with the fashion industry holding a prominent place among the top contributors to this environmental catastrophe.

Amidst growing concerns, a groundbreaking initiative led by textile experts at Heriot-Watt University in the Scottish Borders is set to reshape consumer habits and manufacturing practices in the fashion sector. The team, spearheaded by Dr. Lisa Macintyre, an associate professor at the School of Textiles and Design, has dedicated four years to developing a pioneering tool known as the visual "fiber fragmentation scale."

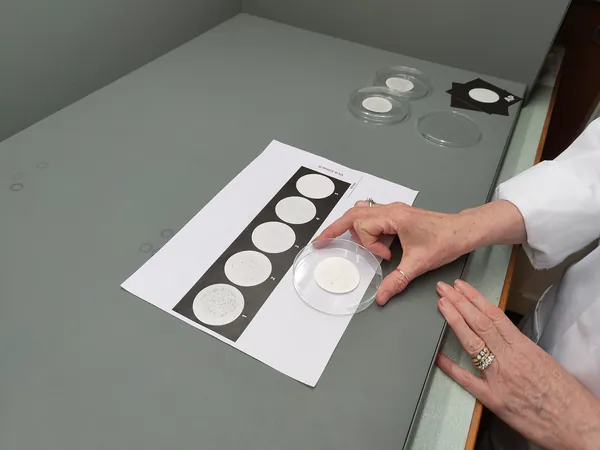

This innovative five-point scale provides a simple yet effective method for assessing fiber pollution from clothing materials. Ranging from one (the highest volume of fiber shedding) to five (the least), this visual grading allows manufacturers and consumers to quickly gauge the environmental impact of their clothing choices.

Not only is this method user-friendly, but it also offers a fast, cost-efficient solution for assessing materials compared to existing alternatives utilized by organizations like the International Organization for Standardization (ISO). Dr. Macintyre notes, “The microplastics problem is massive,” emphasizing the urgent need for tools that help fashion companies minimize their environmental footprint.

The scale is particularly crucial given the pervasive nature of microplastics; they have infiltrated ecosystems from Arctic icebergs to the human food chain, posing significant health risks. The new grading system aims to combat this by facilitating better, more sustainable manufacturing decisions and enhancing transparency for consumers.

To develop the scale, the team employed a specialized machine, known as a "rotawash," which simulates washing machine cycles by applying agitation to textile samples submerged in water. The wastewater containing released fibers was then filtered, allowing participants to visually grade the amount shed against the new scale. The project saw participation from 46 volunteers, including industry professionals and university students, who collectively assessed around 100 samples over two years.

Sophia Murden, a final-year Ph.D. student collaborating with Dr. Macintyre on this project, believes that this visual grading system could become a game-changer in how consumers view textile sustainability. “Our methodology is not only straightforward and economical, but it also allows for a more accurate assessment of low-level fiber fragmentation compared to traditional weighing methods,” she says.

If the fiber fragmentation scale is adopted by the industry, it could be integrated into clothing labels, mirroring the nutritional information displayed on food products. The initiative has garnered interest from established brands like Helly Hansen and Lochcarron of Scotland while aiming to establish a consensus within the industry regarding acceptable fragmentation rates.

Dr. Macintyre is hopeful for future collaborations, stating, “It’s crucial for key industry leaders and policymakers to come together, agree on standards, and potentially legislate against high-shedding materials.” This proactive approach could pave the way for a sustainable future in fashion, one where environmental awareness is just as important as style.

In a world where every garment purchased could either contribute to pollution or promote sustainability, this scale may soon transform consumers into informed advocates for their planet, one clothing choice at a time. Keep an eye on this revolutionary tool – it might just change how you shop for clothes forever!

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)