Unlocking Affordable Hydrogen: A Breakthrough in Fuel Production

2025-04-25

Author: Sarah

Revolutionizing Hydrogen Production

Imagine a future powered by clean hydrogen fuel—an essential piece of the puzzle in combating climate change. While creating hydrogen through the hydrogen evolution reaction (HER) is a reality in the lab, the challenge lies in transforming this process into a cost-effective, large-scale solution.

A Game-Changer from Tohoku University

Researchers at Tohoku University are pioneering a significant breakthrough by employing a surface reconstruction strategy. This innovative approach produces robust, non-noble metal cathodes that significantly accelerate the HER, maintaining their impressive performance for over 300 hours. What’s even more exciting? Their production cost hovers near the U.S. Department of Energy's ambitious target of $2.00 per kilogram of hydrogen by 2026.

From Lab Experiment to Commercial Application

This groundbreaking research could be the key to designing highly efficient, non-noble metal-based cathodes ideal for commercial proton exchange membrane (PEM) applications, effectively bridging the gap between research and real-world usage.

Elevating Efficiency with Transition Metal Phosphides

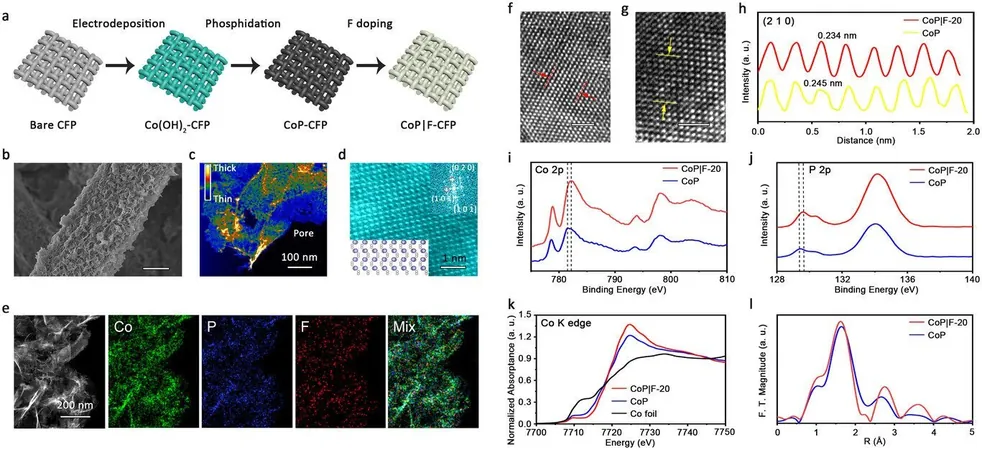

The study's focus on transition metal phosphides (TMPs)—durable and cost-effective alternatives to noble metals—marks a significant advancement. Researchers identified a critical knowledge gap regarding non-noble metals, paving the way for more sustainable options.

Innovative Findings Using Advanced Techniques

By modifying cobalt phosphide (CoP) with fluorine, the research team achieved remarkable results. They utilized cutting-edge operando X-ray absorption spectroscopy (XAS) and Raman measurements to explore the catalyst's activity, enhancing the surface's potential and creating more active sites for the HER.

Impressive Outcomes and Future Prospects

"This reconstructed Co is highly active, operates effectively in acidic conditions, and can sustain about 76 watts over 300 hours," states Heng Liu from the Advanced Institute for Materials Research. The calculated cost for this innovative method? A mere $2.17 per kilogram of hydrogen—only 17 cents above the DOE's 2026 goal.

Significance of This Research

This study does not just stop at lab-scale experiments; it extends its implications to commercial-scale PEM electrolyzers. These findings mark a significant leap forward in HER catalyst research, laying the groundwork for future designs of non-noble metal-based cathodes.

A Vision for the Future

"We’re always focusing on the end goal—to see our research impact everyday life," Liu adds. With these advancements, the dream of affordable, efficient hydrogen fuel is now closer than ever.

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

Česko (CS)

Česko (CS)

대한민국 (KO)

대한민국 (KO)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)

الإمارات العربية المتحدة (AR)

الإمارات العربية المتحدة (AR)