Revolutionary Plasma Technology Amplifies Graphene Production by Over 22%—A Game Changer for Industry!

2024-10-10

Author: William

Revolutionary Plasma Technology Amplifies Graphene Production by Over 22%—A Game Changer for Industry!

Graphene is often hailed as a miracle material, boasting unprecedented properties: it's tougher than diamonds, stronger than steel, as flexible as rubber, and lighter than aluminum. Despite intense interest from researchers and industries alike, affordable and sustainable methods for producing high-quality graphene on a large scale have remained elusive, until now.

A groundbreaking study from researchers at the University of Córdoba (UCO), recently published in the Chemical Engineering Journal, has made a significant leap toward solving this dilemma. Their innovative prototype represents a monumental stride in the quest for mass graphene production—a pursuit that has fascinated scientists since graphene was first synthesized in 2004, earning its discoverers a Nobel Prize six years later.

The UCO team’s new patented design leverages plasma technology, a cutting-edge approach that harnesses a partially ionized gas, known as the fourth state of matter. While natural plasmas can be observed in phenomena like lightning and the aurora borealis, this method allows for controlled, artificial generation of plasma within a laboratory setting.

Lead author Francisco Javier Morales emphasized that the immense energy of plasma makes it particularly adept at breaking down organic molecules. By employing a plasma torch, the research team was able to decompose ethanol and rearrange its carbon atoms, resulting in a new, effective method for synthesizing graphene.

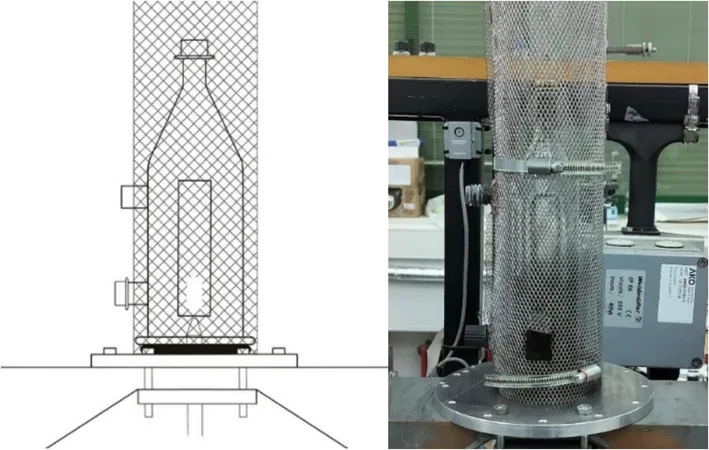

Optimizing Energy with a Faraday Cage

One of the most exciting aspects of this development is the energy optimization that the team successfully achieved. Previous research revealed that nearly 43% of the energy used in conventional graphene production was lost as waste. Recognizing this inefficiency, the researchers designed a Faraday cage—an electromagnetic shield crafted from metal mesh akin to technology used in microwave ovens—to encase the plasma. This clever modification maximizes the energy harnessed during the graphene synthesis process.

According to principal investigator Rocío Rincón, this design enhancement allows the production rate of graphene to jump significantly—from 4.3 milligrams per minute per watt to an impressive 5.2 milligrams under the same conditions, representing a notable 22% increase.

This advancement is particularly crucial as the demand for graphene grows across multiple industries, from electronics to materials engineering, where its unique characteristics could revolutionize existing technologies. The implications of this breakthrough extend far beyond research; it could pave the way for scalable, sustainable production methods that finally bring graphene from the lab to the marketplace.

As scientists race to explore the full potential of graphene, the UCO team’s work exemplifies how innovative approaches to energy efficiency can lead to transformative changes in industrial materials production. The future is indeed bright for graphene, and with this new technological edge, we may soon witness its integration into everyday applications that could change our world. Are we on the brink of a graphene revolution? Only time will tell!

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)