The Comeback of Sony Vaio: A Deep Dive into Reviving a Classic Laptop

2024-12-16

Author: Charlotte

Introduction

In the tech world, few brands evoke nostalgia quite like Sony's Vaio line of laptops. With their unique design and portability, these devices have garnered a loyal following, and one dedicated individual has embarked on an ambitious journey to revive one such classic. This intriguing project centers around the redesign of the Sony Vaio's mainboard, challenging conventions and showcasing modern engineering capabilities.

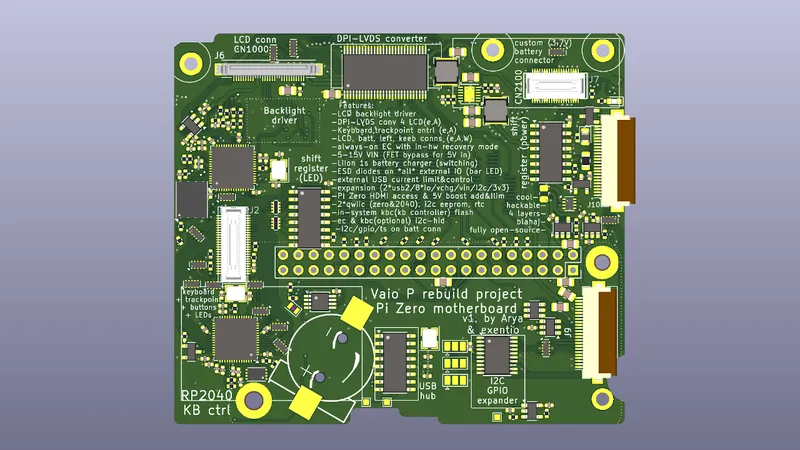

With a captivating combination of charm and compactness, this specific Vaio model is both aesthetically pleasing and functional. The available motherboard schematics add a significant advantage for enthusiasts looking to breathe new life into their aging devices without breaking the bank. In fact, the primary motivation for this project arose from the owner's desire to restore their own Vaio, which has seen better days. The undertaking has proven to be more complex than anticipated, presenting a steep learning curve that exceeded initial expectations. However, the first version of the PCB (Printed Circuit Board) design has yielded promising results, with only a few components yet to be tested.

For many tech aficionados, similar projects abound – with countless DIY enthusiasts chronicling their journeys online. Notably, many have even transformed old Vaio models into innovative devices, such as Pi-powered handhelds, exemplifying creativity and resourcefulness in the maker community. In honor of every aspiring engineer with half-finished projects gathering dust, this piece will outline the strategies and lessons learned from this Vaio revival effort.

Mastering Space Constraints: Planning for Success

Recently, the first revision of the new motherboard successfully passed tests, demonstrating the effectiveness of a four-layer design populated on both sides. This restructuring was no easy feat—requiring a careful balance of high-level and low-level decision-making to ensure functionality despite spatial limitations. One helpful tip that emerged during the planning phase was the importance of delineating component locations using placeholders on the silkscreen layer. This saved considerable time and effort later in the layout process.

Start by selecting the right size for passive components to maximize efficiency. For this project, 0402-sized components were chosen to accommodate the compact space while allowing for a streamlined assembly process. The dual-channel buck regulator and USB hub were essential blocks integrated into the design, and sourcing standardized components ensured consistency and ease when ordering.

It cannot be emphasized enough how vital daily consistency proved, dedicating just an hour or two to this project each day made a world of difference. Large projects like this often take weeks to see completion, and keeping a well-maintained TODO list in the schematic provided clarity on essential tasks, from designs to potential pitfalls to be aware of.

Navigating Challenges with Component Sourcing

Ensuring all components are accounted for at the start is crucial to maintaining project momentum. The dream scenario is to order all necessary components early to avoid hiccups, particularly with vital resistors and feedback loops, which can lead to costly delays. Adjusting resistor values during assembly also affords flexibility and ease of troubleshooting any issues during the bring-up process.

The creator's experience was vastly improved thanks to a remarkable resource known as the Interactive HTML BOM for KiCad, which streamlined the assembly process and reduced potential errors. Furthermore, the experience emphasized the significance of planning prior to commencing board design—ensuring the smart use of space, particularly when integrating larger components like inductors.

Design Optimization: Keeping it Functional and Efficient

The motherboard's complexity required intelligent layering to maximize the board's utility, implementing a configuration of SIG-GND-PWR-SIG for optimal signal return currents. Each layer was designed to balance performance with necessary space constraints while preventing the board components from overheating—an especially crucial consideration for tight designs like this one.

The cumulative efforts led to an effective project that serves as a testament to the revival of a beloved Sony Vaio laptop. Beyond just restoration, it illustrates the endless possibilities that innovation and collaboration can create in the tech community. Workers and engineers alike are encouraged to embrace their creativity and consider the potential of outdated technology.

As the final assembly and testing approach, the anticipation builds. With the first successful results in hand, this project aims to inspire others to consider their own approaches to reviving machines that once captivated the hearts of users worldwide. Unleashing the full potential of a classic model is not simply about nostalgia; it's about celebrating engineering and innovation that can thrive across generations.

The final result is soon to be unveiled, and the excitement surrounding the revamped Vaio continues to grow. Stay tuned for insights on performance and functionality as this beloved device gears up for a new chapter.

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)